The difference between HDPE and PPR pipes and what service installations can use HDPE and PPR pipes?

- N.T.R Partners

- May 9, 2024

- 5 min read

At N.T.R. Partners We have the knowledge and expertise in installing plastic pipes. And we understand that choosing the right material for water pipe installation is extremely important. In this article, we will discuss the differences between HDPE and PPR pipes and tell you what type of service installation each material is suitable for.

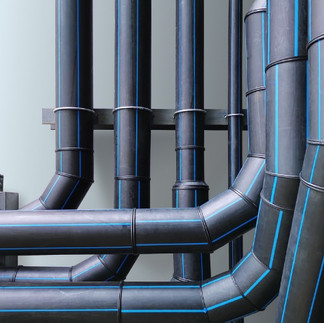

HDPE pipe:

HDPE and PPR pipes are commonly used materials for water pipe installation. HDPE pipes are strong and resistant to chemical corrosion, while PPR is flexible and resistant to breakage. In this article, we will explain the differences. The difference between HDPE and PPR pipes and is to suggest which type of service installation is appropriate for each material.

Contact N.T.R. Partners for a quotation on your project www.ntr-partners.com E-mail: info@ntr-partners.com Mobile: 0644649242

Comparison of HDPE and PPR Pipes

Features of HDPE Pipes

HDPE or High-Density Polyethylene is a plastic material with a high density. It is strong and resistant to friction. In addition, HDPE is highly flexible. This makes it easy to install and maintain. Additionally, HDPE is resistant to chemicals, sunlight, and high temperatures. This makes it ideal for use in distressed environments.

Features of PPR Pipes

PPR or Polypropylene Random is a plastic material that is strong and resistant to friction. In addition, PPR is resistant to heat and cold. Can be used in both high and low temperature conditions. In addition, PPR is resistant to chemicals. It has a long service life and is easy to install.

Therefore, choosing to use HDPE or PPR depends on the nature and needs of the project. If you want to use it in harsh environments and require high flexibility. and resistance to friction You should choose to use HDPE, but if you want to use it in high and low temperature conditions. and require chemical resistance You should choose to use PPR.

Contact us to request a quote for installation of both HDPE and PPR Pipes for various services.

Contact N.T.R. Partners for a quotation on your project www.ntr-partners.com E-mail: info@ntr-partners.com Mobile: 0644649242

Applications of HDPE Pipes

Water usage

HDPE Pipes are suitable for water supply applications because they are resistant to water leakage. And is resistant to corrosion from chemicals that are often present in tap water. In addition, HDPE Pipes can withstand high pressure. and has a long service life

Drainage use

HDPE Pipes are suitable for drainage applications. Because it is resistant to corrosion from chemicals that are often present in water. And is resistant to high water pressure. In addition, HDPE Pipes can withstand shock well.

Industrial use

HDPE Pipes are suitable for industrial applications. Because it is resistant to corrosion from chemicals. and is resistant to high pressure. In addition, HDPE Pipes are able to absorb shock well. This makes it suitable for use in places where there is movement of materials and machinery.

Usage of PPR Pipes

PPR pipes being installed in a plumbing system, while HDPE pipes are used for outdoor water supply. Both pipes are being compared for their different applications

Use in heating systems

PPR Pipes are suitable for use in heating systems. Especially in use in water heating systems. It can withstand heat up to 95 degrees Celsius and has quick and easy installation. Moreover, there is no heat buildup. no leakage and does not affect human health

Use in drinking water systems

PPR Pipes are suitable for use in drinking water systems. It can withstand pressure up to 20 bars and has non-toxic properties and is highly clean. There is also no accumulation of various chemicals. and there is no corrosion or rust.

Use in building systems

PPR Pipes are suitable for use in building systems such as air conditioning systems. Ventilation system, water supply system, and more. It can withstand pressure up to 20 bars and has features that are durable for long-term use. There is also no chemical buildup. and there is no corrosion or rust.

If you want to install PPR Pipes in your system Please contact us for an installation quote. Our team has more than 10 years of experience in installing PPR Pipes and has good service quality. and a price that suits your budget

Installation steps and instructions

An installer connects HDPE & PPR pipes, showing differences. No human presence

When choosing to use HDPE or PPR pipes for service installation The installation steps must be followed for effective use as follows.

HDPE pipe installation

Check and prepare the installation area There must be enough space for work and the necessary tools.

Check and choose HDPE pipes that are of good quality and have the appropriate size for use.

Check and select appropriate equipment such as joints, pipes and other accessories.

Install HDPE pipes using the correct tools and methods. and must be careful to prevent pipe destruction.

Test the functionality and check the completeness of the installation.

PPR pipe installation

Check and prepare the installation area There must be enough space for work and the necessary tools.

Check and choose PPR pipes that are of good quality and have the appropriate size for use.

Check and select appropriate equipment such as joints, pipes and other accessories.

Install PPR pipes using the correct tools and methods. and must be careful to prevent pipe destruction.

Test the functionality and check the completeness of the installation.

We have a team of experts with experience in installing HDPE and PPR pipes and are ready to provide installation services in every area. Type of service

We provide high quality and efficient HDPE and PPR pipe installation services to our customers. We have a team of experts with experience and expertise in installing HDPE and PPR pipes in all types of projects. Whether it's a big or small project, it can be done easily.

We provide HDPE pipe installation services for jobs that require durability and strength, such as drinking water pipes, wastewater pipes, electrical conduits, and many others. HDPE pipes are resistant to pressure and breakage well.

For PPR pipes, we provide installation services for jobs that require flexibility and heat resistance, such as hot water pipes, gas pipes, and plumbing pipes. PPR pipes have good heat resistance and strength.

If you would like to request an installation quote Please contact us for consultation and high-quality, high-performance HDPE and PPR pipe installation services to serve our customers.

Contact N.T.R. Partners for a quotation on your project www.ntr-partners.com E-mail: info@ntr-partners.com Mobile: 0644649242

Frequently asked questions

What is the difference between HDPE pipe and PPR pipe?

HDPE pipes and PPR pipes are what are used to transport water and other liquids. The two types are very different. HDPE pipes are very flexible and can withstand high pressure, while PPR pipes are heat resistant and a strong plastic. Therefore, choosing the right pipe for the job we want is important.

What is the price difference between HDPE pipe and PPR pipe?

The prices of HDPE pipes and PPR pipes vary greatly. The price of PPR pipes is higher than HDPE pipes because the plastic material used in their production is stronger and more resistant to heat. But both types of pipes are suitable for different applications. Therefore, choosing the right pipe for the job we want is important.

What is the method of connecting HDPE pipe to PPR pipe?

Connecting HDPE pipes to PPR pipes requires proper connection methods, such as using appropriate couplings for the pipes used in that job. Proper connections prevent leaks of water and other liquids. that could happen

What are the disadvantages of PPR pipes?

The disadvantage of PPR pipes is that compared to HDPE pipes, PPR pipes are more expensive. and cannot withstand high pressure as HDPE pipes, but PPR pipes are resistant to heat and are strong plastics.

Contact N.T.R. Partners for a quotation on your project www.ntr-partners.com E-mail: info@ntr-partners.com Mobile: 0644649242